Rapid prototyping is a technique used in industrial design to quickly and efficiently create physical models of a product. This process, also known as prototype manufacturing and rapid prototype development, allows designers and engineers to test the form, fit, and function of a product before it goes into mass production. In this article, we will discuss how rapid prototyping is applied in industrial design, with a focus on prototype manufacturing and development.

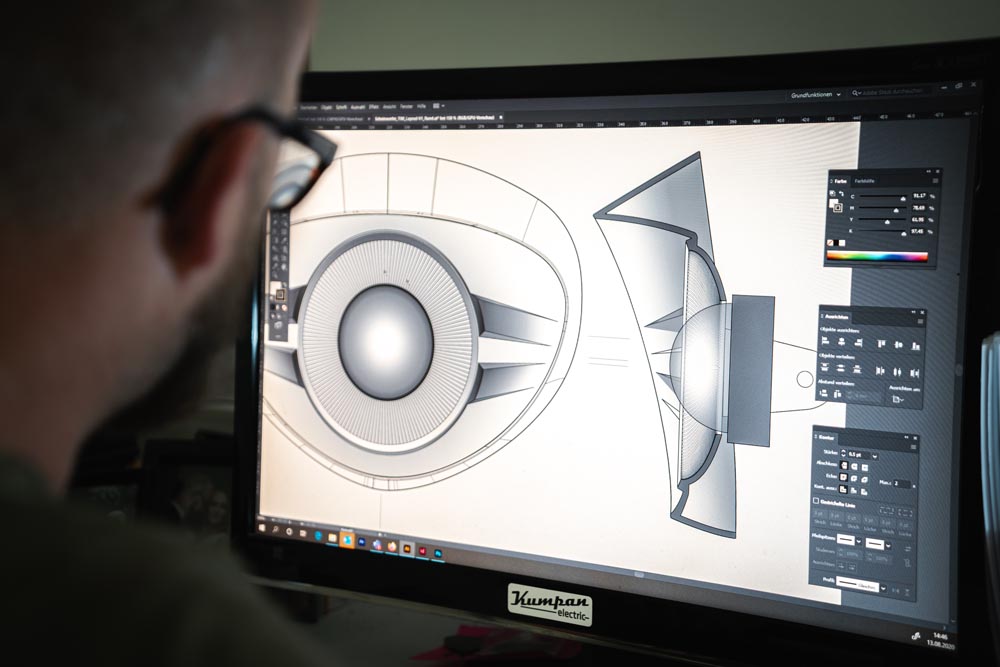

The industrial design process typically begins with a concept or an idea for a product. This idea is then transformed into a digital model using computer-aided design (CAD) software. Once the digital model is complete, it can be used to create a physical prototype using rapid prototyping techniques such as 3D printing, CNC machining, and vacuum casting.

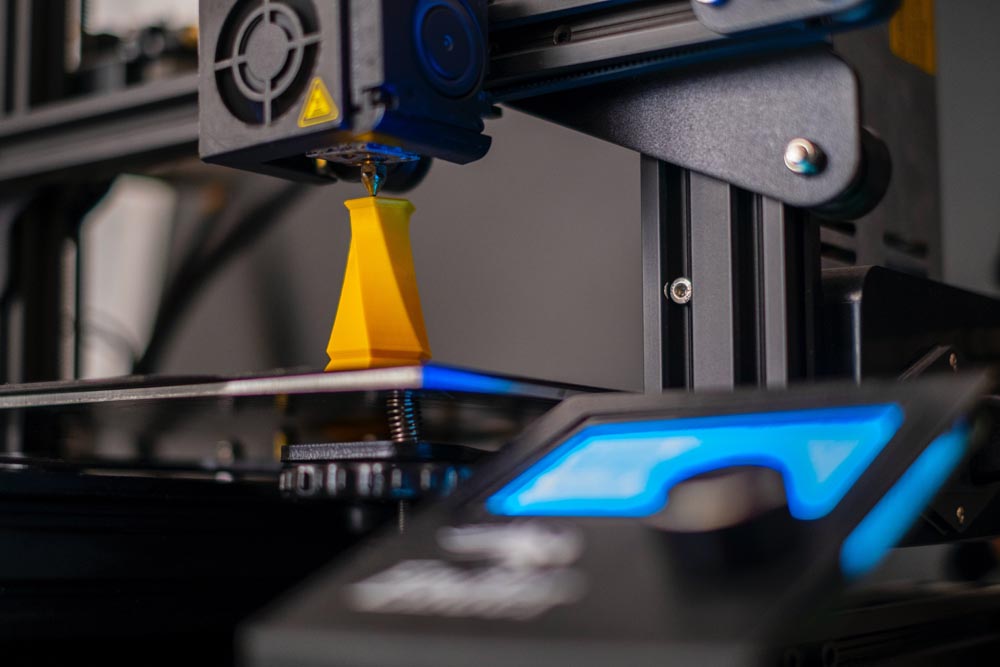

One of the most popular rapid prototyping methods used in industrial design is 3D printing. This technique uses a digital model to create a physical object by laying down successive layers of material. 3D printing can produce prototypes quickly and at a relatively low cost, making it a popular choice for industrial designers for prototype development.

Another rapid prototyping method used in industrial design is CNC machining. This method uses a computer-controlled machine to cut and shape a prototype from a block of material. CNC machining is often used to create prototypes that require high levels of accuracy and precision, and it’s also crucial and widely applied in prototype manufacturing.

Rapid prototyping in industrial design allows designers and engineers to test the form, fit, and function of a product before mass production. This allows for any design issues to be identified and addressed early on in the development process. It also allows for a product to be refined and improved before it reaches the consumer through prototype development.

Rapid prototyping can also be used to create a low-volume production of a product. This is known as small-batch production, and it is often used to create prototypes for testing and evaluation before a product goes into mass production. The use of prototyping manufacturing rapid can help to produce a small number of prototypes in a short period of time, which can be used for testing and evaluation.

Rapid prototyping can be an extremely powerful tool in industrial design, allowing designers and engineers to quickly and efficiently create physical models of a product.

In conclusion, rapid prototyping is a valuable tool for industrial designers. It allows for the rapid creation of physical models, which can be used for testing, visualizing and promoting ideas. Rapid prototyping technologies such as 3D printing, CNC machining, and vacuum casting can produce high-quality, detailed models that closely resemble final products. Additionally, the ability to quickly iterate and make changes to the design allows for more efficient product development and faster time to market. The integration of rapid prototyping into an industrial design can lead to more innovative and successful products. Overall, it is a powerful tool that is essential for any industrial design process.