In manufacturing, throughput is the rate at which a company produces or processes its products. The goal is always to maximize throughput without compromising quality or efficiency. This balance is particularly challenging in industries that rely heavily on fluid dynamics, such as in the operation of hydraulic systems. Advanced hydraulic systems are pivotal to improving throughput as they directly influence production lines’ speed, efficiency, and reliability. After all, what could be more critical to a manufacturer than ensuring that production flows as smoothly and swiftly as possible? Isn’t it true that the strength of a chain is determined by its weakest link?

Practical Components

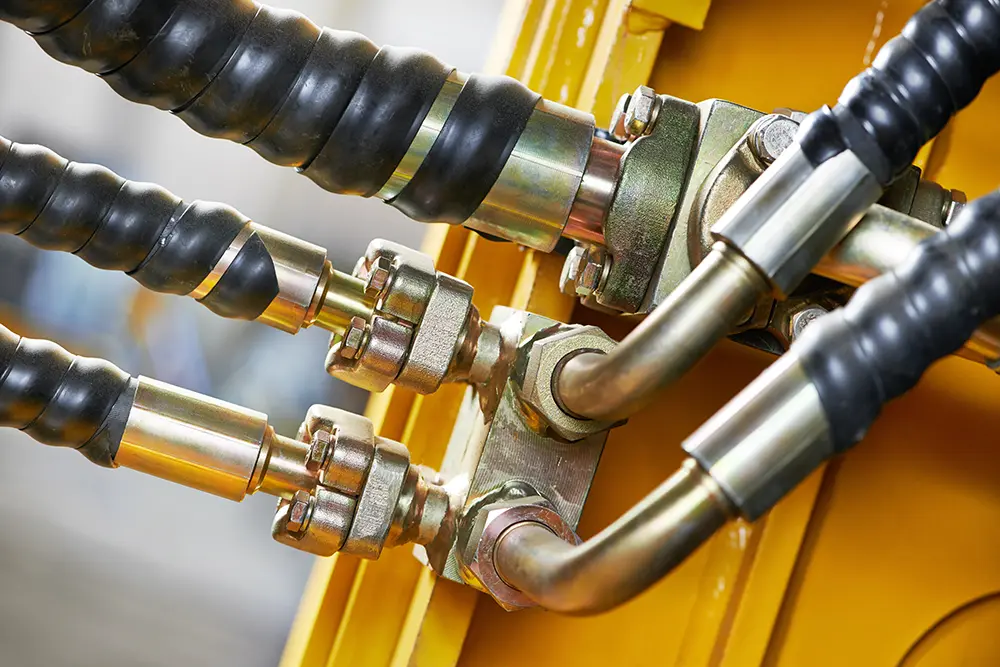

Even seemingly minor components, such as hydraulic hose adapters, valves, and seals, play a significant role in the efficiency and reliability of hydraulic systems. For instance, these adapters ensure secure connections and maintain the integrity of the hydraulic fluid path, which is critical for system performance and manufacturing throughput. Similarly, valves regulate the flow and direction of the fluid, while seals prevent leaks that could compromise the entire system’s functionality. This attention to detail in component selection and system assembly highlights the importance of every single piece of the puzzle. When even the most minor parts are optimized for peak performance, the entire system functions more smoothly, mirroring the principle that every chain is only as strong as its weakest link.

The reliability of the adapters, alongside valves and seals, directly influences the operational uptime of manufacturing equipment. A leak or a fault in one of these components can lead to system failures, causing unplanned downtime that can cripple production schedules. Hence, choosing high-quality adapters, robust valves, and effective seals becomes a matter of maintaining system integrity and a crucial strategy in minimizing disruption and maintaining a steady production flow. These components are not merely connectors but guardians of the hydraulic system’s continuity, ensuring that every aspect of the system contributes positively to the manufacturing process.

The Role of Advanced Hydraulic Systems

Hydraulic systems are integral to manufacturing operations, powering everything from assembly lines to heavy machinery. These systems use fluid power to perform work, making them highly efficient and capable of precisely handling substantial loads and applications. The advent of advanced hydraulic systems, which incorporate better materials, smarter design, and enhanced control technologies, has significantly uplifted the manufacturing sector’s capability to increase throughput. It’s like giving the industry a much-needed adrenaline shot, allowing it to run faster and longer than ever before. With these upgrades, machines work harder and smarter, adapting quickly to the demands of high-volume production environments.

One of the critical advancements in hydraulic systems is real-time data monitoring and control systems. These technologies allow for precise control of hydraulic pressure, flow, and temperature, ensuring optimal performance and minimal downtime. By constantly adjusting parameters, these systems prevent the inefficiencies and mechanical failures that often slow down production lines. This innovation is akin to having a skilled conductor leading an orchestra, where every movement is coordinated to produce a flawless performance. Such meticulous management of system variables ensures that production never misses a beat, setting the stage for unparalleled efficiency.

Efficiency and Sustainability

Another significant benefit of advanced hydraulic systems is their contribution to sustainability. These systems are designed to minimize waste through improved energy efficiency and reduced fluid consumption. By using high-efficiency pumps and motors, manufacturers boost their throughput and reduce energy costs and environmental impact. This focus on sustainability is not just about saving money—it’s about ensuring that future generations inherit a healthier planet. In a world increasingly concerned with environmental stewardship, such forward-thinking practices are not just beneficial but essential.

Moreover, integrating robust sealing technologies and corrosion-resistant materials extends the lifespan of hydraulic components and systems. This durability reduces the need for frequent replacements and maintenance, enhancing production continuity and throughput. By strengthening the backbone of hydraulic machinery, manufacturers can avoid the downtime that often undermines productivity and profitability. It’s a straightforward equation: longer-lasting components plus fewer breakdowns equals sustained manufacturing success.

Cost Implications and ROI

Investing in advanced hydraulic systems might seem costly upfront, but the return on investment (ROI) is often quickly realized through increased throughput and reduced operational costs. Modernizing hydraulic systems can lead to significant reductions in production bottlenecks, mechanical failures, and maintenance downtime, all of which contribute to overall cost savings. It’s like priming the engine of productivity to fire on all cylinders—once the initial adjustments are made, the performance improvements can be dramatic and financially rewarding.

Furthermore, the flexibility of advanced hydraulic systems allows for scalability. Manufacturers can easily upgrade or expand their systems to meet increased production demands without complete overhauls. This scalability makes them cost-effective and future-proofs production lines against changing market demands. As markets evolve and production needs shift, this adaptability becomes a strategic advantage, enabling businesses to respond dynamically to new opportunities without missing a beat. This isn’t just planning for tomorrow; it’s securing a foothold in the future of manufacturing.

Challenges and Solutions

Despite their benefits, advanced hydraulic systems come with challenges. Their complexity requires skilled technicians for operation and maintenance. Integrating new hydraulic systems with existing machinery and processes can also be complex and time-consuming. The steep learning curve associated with these systems can initially hinder their adoption, but this barrier is typically overcome as teams grow more proficient over time.

However, these challenges can be mitigated through proper training and the gradual integration of advanced systems. Additionally, manufacturers can work with hydraulic system providers who offer comprehensive support and customization options to ease the transition and maximize the systems’ effectiveness. By taking these steps, companies can transform potential obstacles into opportunities for growth and innovation, ensuring that the advanced capabilities of hydraulic systems fully align with their operational needs and goals.

Conclusion

Integrating advanced hydraulic systems in manufacturing is not just about upgrading equipment; it’s about transforming processes to achieve higher throughput and efficiency. With suitable investment, manufacturers can significantly enhance their production capabilities, paving the way for increased profitability and growth. As technology continues to evolve, the potential for further improvements in throughput through advanced hydraulic solutions looks both promising and essential for the future of manufacturing. Isn’t it remarkable how today’s innovations can become tomorrow’s industry standards?