Introduction: Why are proper winter work gloves essential?

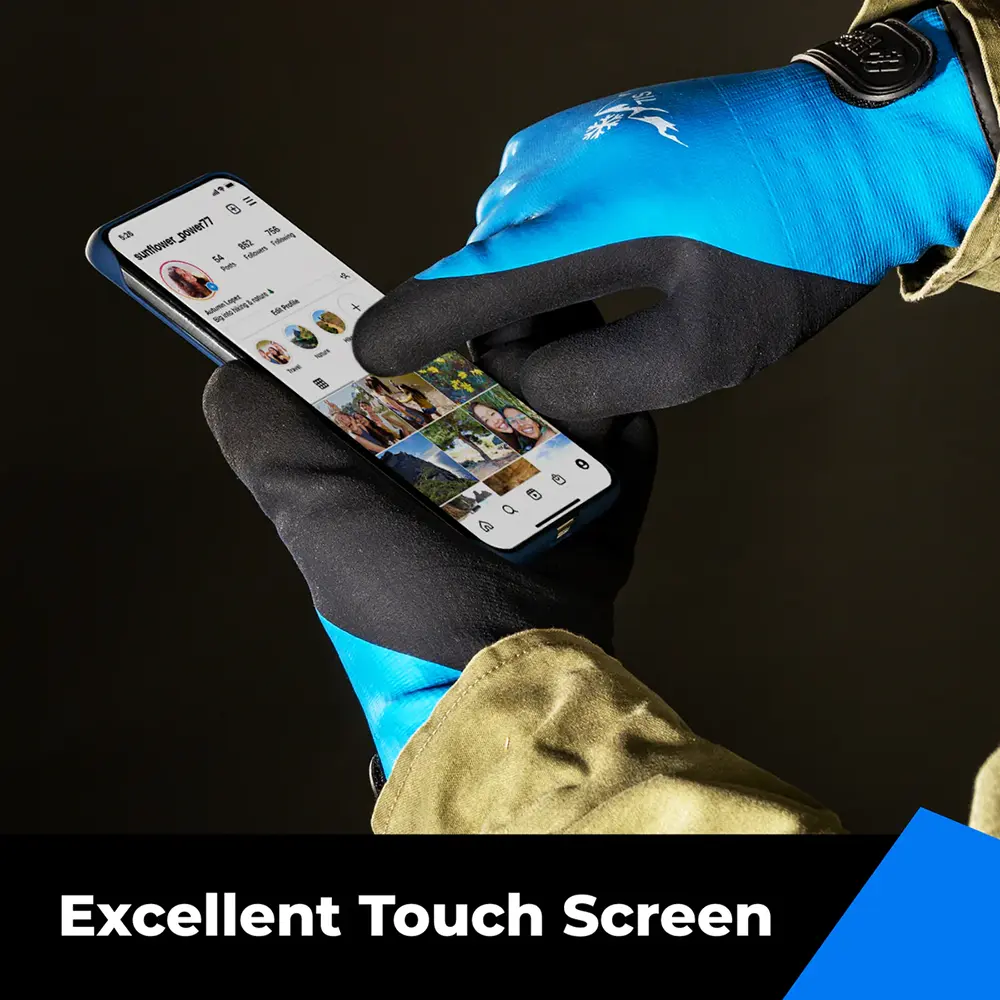

Winter work gloves are an essential part of personal protective equipment (PPE) for people who work in cold and harsh weather conditions. Hands become vulnerable to threats as temperatures drop and frigid winds lash through outdoor surroundings. Workers face a higher risk of pain, injury, and decreased productivity if they are not adequately protected. Investing in high-quality winter work gloves is an issue of comfort in this environment and an essential safety measure. This article will go into why these gloves are necessary for those who work throughout the winter months, examining the numerous hazards they minimise and the benefits they provide in ensuring a safe and efficient work environment.

Types of materials used in winter work gloves and their benefits;

Winter work gloves are made from various materials, each with its advantages customised to certain working circumstances and duties. Whether shovelling snow or hiking, toolant winter gloves are a must-have accessory. Here are some popular materials used in winter work gloves, as well as their benefits:

1. Leather:

Leather gloves are frequently coated with materials such as Thinsulate or fleece, which provide good insulation against the cold.

Leather is a rigid material that is resistant to abrasion and wear. It can tolerate brutal handling and extreme environmental conditions.

Water Resistance: Leather gloves, while not waterproof, can provide some water resistance, keeping hands dry in mild rain or snow.

2. Nitrile:

Waterproofing: Nitrile is a synthetic substance that is highly resistant to water. In rainy weather, nitrile-coated gloves help keep hands dry.

Dexterity: Nitrile gloves are generally flexible and have high tactile sensitivity, allowing for precise item handling.

3. Neoprene:

Chemical Resistance: Because of its resistance to a wide range of chemicals and oils, neoprene is ideal for duties involving the handling of hazardous substances.

Waterproofing: Neoprene is highly water resistant, keeping hands dry in wet conditions.

4. PVC (Polyvinyl Chloride):

Insulation: PVC gloves are frequently insulated with fleece or thermal materials to provide warmth in cold weather.

Water Resistance: Because PVC is naturally water-resistant, these gloves are excellent for use in wet conditions.

5. Thermal Linings (such as Thinsulate and Fleece):

Warmth: When used with other materials, these linings provide more incredible warmth in frigid weather.

Moisture Wicking: Many thermal linings are designed to wick moisture away from hands, keeping them dry.

6. Gore-Tex:

Breathability: Gore-Tex is a breathable, waterproof textile that is frequently used as a glove lining. It lets moisture escape while keeping water out, keeping your hands dry and comfortable.

7. High-Visibility Materials:

Safety: Some winter work gloves include high-visibility materials such as reflective strips or colours to improve visibility in low-light circumstances, boosting workplace safety.

Rubber: Waterproofing: Because rubber gloves are waterproof, they are great for work involving water, snow, or ice.

8. Kevlar:

Cut Resistance: Kevlar is a high-strength synthetic material that is well-known for its cut and abrasion resistance. Gloves reinforced with Kevlar are appropriate for work involving the handling of sharp items.

9. Dexterity:

Goatskin is a soft and pliable material that provides good dexterity and tactile sensitivity. It is appropriate for jobs that demand precision.

Choosing the best material for winter gloves is determined by the job’s unique tasks, ambient conditions, and safety needs. Workers may make informed choices to ensure their hands are sufficiently protected during winter work by studying the qualities and benefits of each material. The reinforced palms of the toolant gloves prevented any abrasions or blisters, even after hours of intensive work.

How to properly care for your winter work gloves to ensure longevity?

Winter work gloves must be appropriately cared for to preserve their longevity and efficiency in protecting your hands during cold and brutal conditions. Here are some suggestions for managing your winter work gloves:

- Cleaning regularly: It is critical to clean your gloves regularly to keep them in good condition. Most glove materials can be cleaned simply by wiping them down with a moist cloth. To remove dirt and stains from leather gloves, use a leather cleaner. To avoid mould and odours, make sure they are dehydrated before storage.

- Avoid Excessive Moisture Exposure: Excessive moisture can weaken and destroy the structure of your gloves. Allow your gloves to air dry at room temperature if they become wet. Direct heat sources, such as radiators or hairdryers, should be avoided since intense heat might cause the materials to break or shrink.

- Keep your gloves in a cool, dry area away from direct sunlight when not in use. Ensure the gloves are completely dry before storing them since moist gloves can develop mould and a musty odour. Crumpling or folding gloves can cause wrinkles that weaken the material.

- Avoid Using Excessive Force: Consider the work you undertake with your gloves. Excessive force or rough treatment can result in premature wear and tear. To avoid cuts or punctures when working with sharp things, try using gloves made of reinforced materials such as Kevlar.

- Use Protective Creams (for Leather Gloves): Leather gloves benefit from regularly using leather conditioner or cream. This helps keep the leather supple and from drying out and cracking.

- Examine for Damage: Inspect your gloves regularly for signs of wear and damage, such as holes, fraying, or loose stitching. If you discover any problems, it is critical to repair or replace the gloves as soon as possible to keep their protective capabilities.

- Rotate Gloves: If you have many pairs of gloves, rotate them to disperse wear evenly. This can help extend each team’s life while ensuring that you always have a dependable set on hand.

- Follow the manufacturer’s directions: Always adhere to the manufacturer’s care recommendations. Different materials may necessitate special attention.

- Keep Your Hands Clean: Before putting on your gloves, make sure your hands are clean. Your skin’s oils, debris, and chemicals can destroy the materials over time.

- When necessary, replace: Regardless of how well they are cared for, all gloves have a finite lifespan. When your gloves no longer provide proper protection or have become considerably worn, it’s time to replace them. Take your time with safety.

Properly caring for your winter work gloves increases their lifespan and guarantees that they continue to provide the protection you require in inclement weather. Toolant gloves keep your hands warm and protected when working in cold weather. By following these maintenance instructions, you can keep your gloves in good shape and decrease the need for replacements.

Conclusion:

Finally, paying close attention to preserving your winter work gloves is essential for anybody confronted with the problems of cold and harsh weather conditions. Following these simple but practical instructions may extend your gloves’ life while maintaining their protective properties. Regular cleaning, correct storage, and timely repairs are just a few steps that can significantly increase the life of your gloves. Remember to follow the manufacturer’s recommendations and look for signs of wear and tear. By devoting time and effort to maintaining your gloves, you ensure their durability and the safety and well-being of your hands during strenuous winter work. Finally, a well-maintained pair of gloves is a priceless treasure, giving dependable protection and comfort even in extreme conditions.