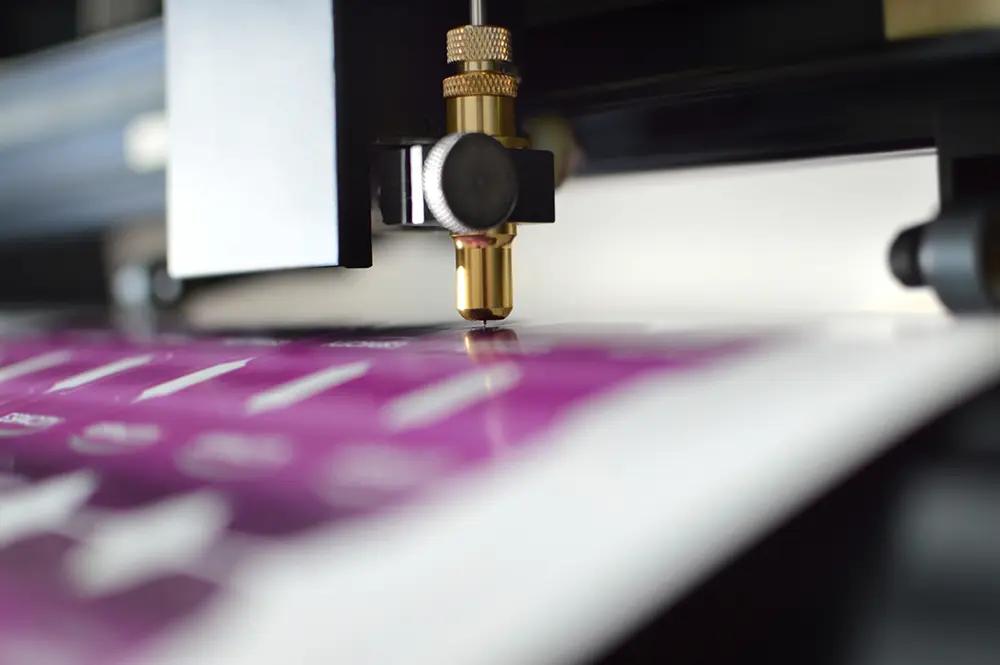

A vinyl cutter is a versatile and essential tool in the realm of graphic design, crafting, and signage production. Also known as a plotter, it is a device that precisely cuts designs and shapes from vinyl sheets or rolls. The machine operates by following digital vector files created with design software, allowing for intricate and detailed cuts.

The process involves loading a vinyl sheet into the cutter, setting the parameters such as speed and pressure, and then letting the machine precisely cut the desired design. It can be challenging to get started in the large and interesting field of graphic design, but it can be a lot of fun, whether you approach vinyl cutter as a hobby or a business. It’s one of the most widely used techniques for making scrapbooks or home décor pieces.

A vinyl plotter cutter can now be used to create signage and sell vinyl decals. Vinyl cutting machines come with blades that can cut different forms and designs into materials, despite the wide variety of shapes and sizes available.

Majors Factors For Considering Purchase of Vinyl Cutters

The flexibility of vinyl cutters extends to crafting, where enthusiasts use them to cut intricate shapes for various projects. From stickers and decals to home decor items, a vinyl cutter opens up a realm of creative possibilities.

Overall, the vinyl cutter’s role is central to the production of precise and customized designs across diverse applications, making it an indispensable tool for businesses and hobbyists alike. Choosing the right vinyl cutter is crucial for achieving precision and efficiency in your cutting projects. Here are several major factors to consider when buying a vinyl cutter:

Cutting Size & Force

Evaluate the cutting width and size of the vinyl cutter. Consider the maximum width of materials you plan to work with. Larger cutting widths are suitable for bigger projects, while smaller machines may suffice for more compact designs. The cutting force determines the thickness and type of materials the vinyl cutter can handle. If you plan to work with thick or dense materials, ensure that the cutter has sufficient cutting force to handle the job effectively.

Speed Settings

Look for a vinyl cutter with adjustable speed settings. Different materials and designs may require varying cutting speeds. Having control over the speed allows you to optimize the cutting process for different projects.

Software Compatibility

Check the compatibility of the vinyl cutter with design software. Most vinyl cutters come with proprietary software, but it’s essential to ensure that it supports popular design formats such as SVG, DXF, and AI. Compatibility with third-party design software can also be an advantage.

Ease of Use

Consider the user-friendliness of the vinyl cutter, especially if you are a beginner. A straightforward interface and easy-to-understand controls can save time and reduce the learning curve. Look for features like touchscreen displays and intuitive software.

Material Compatibility

Ensure that the vinyl cutter is compatible with a wide range of materials. Different projects may require cutting materials like adhesive vinyl, heat transfer vinyl, or even thicker materials like cardstock or leather. A versatile cutter allows for a broader range of applications.

Tracking and Registration

Accurate tracking and registration are crucial for precision cutting. Look for a vinyl cutter with advanced tracking systems to ensure that the machine follows the cutting path accurately. This is particularly important for intricate and detailed designs.

Integration with Printers

If you plan to create print-and-cut projects, choose a vinyl cutter that integrates well with printers. Print-and-cut capabilities enable you to print designs and then have the vinyl cutter precisely cut around them, streamlining the production process.

Build Quality and Durability

Assess the build quality and durability of the vinyl cutter. A sturdy and well-built machine is likely to last longer and withstand the demands of regular use. Look for models with robust construction and quality materials.

Customer Support and Warranty

Research the manufacturer’s reputation for customer support and the warranty offered with the vinyl cutter. When you run into problems or have inquiries, having dependable customer service may be quite helpful. A solid warranty provides peace of mind and indicates the manufacturer’s confidence in their product.

Price and Budget

Determine your budget and compare the features offered by different vinyl cutters within that price range. While it’s essential to stay within budget, consider the long-term value and capabilities of the machine to ensure it meets your current and future needs.

Bottom Line

Whether you’re a small business owner looking to create custom signage or an avid crafter wanting to add personalized touches to your projects, a vinyl cutter opens up a world of creative possibilities with its precision and flexibility in material compatibility. Vinyl cutters are widely used in various industries, including advertising, apparel customization, and crafting. They play a crucial role in creating vinyl decals, stickers, lettering, and even heat-transfer designs for textiles.