The world of engineering is constantly changing and evolving. Thanks to technology, there’s so much more that designers and engineers can do when it comes to creating products from scratch.

Lattice structures are a great way to develop highly functional parts and products that are revolutionary. But what are lattice structures and how do they benefit designers and engineers responsible for creating the latest and best products on the market?

In this article, you’ll get a beginner’s guide to lattice structures. This introduction will explain what they are and how they’re applied within the world of design and engineering. We’ll also explore the benefits of this process and how it might change the performance and outcome of future products.

What are lattice structures?

Lattice structures are topologically ordered, meaning they have a linear ordering. They’re three-dimensional, open-celled structures, and they’re made up of one or two repeating unit cells.

The properties of this structure are often directly related to the size, shape, structure, geometric size, and spatial arrangement of the cells. Lattice structures are often commonly used in manufacturing and in particular, additive manufacturing.

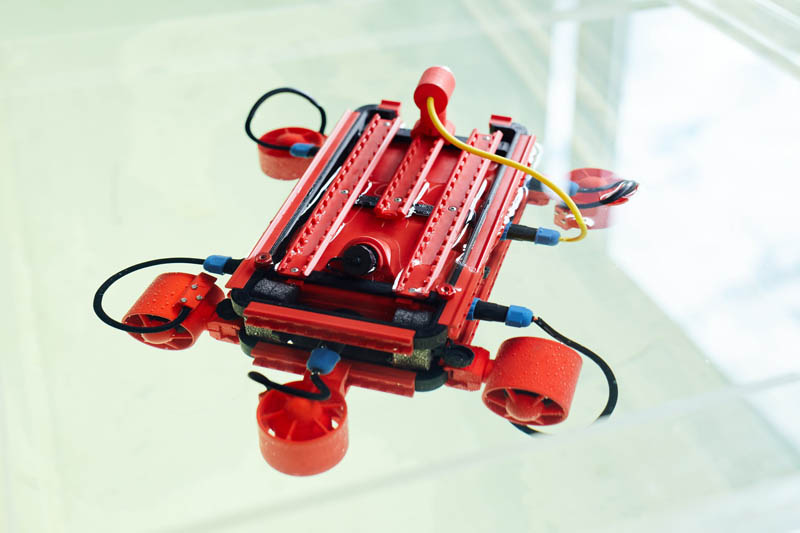

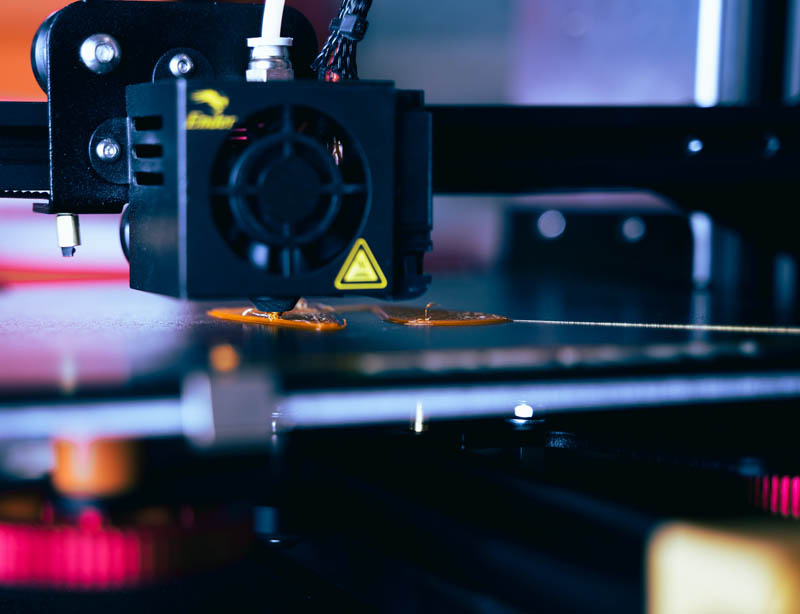

Additive manufacturing is otherwise known as 3D printing and it’s used a lot in the design and manufacturing of product development nowadays. With lattice structures, you can think of them as mini architectures that consist of a network of beams and nodes. These reduce weight considerably whilst still retaining the integrity of its structure.

So how are they used and how do they benefit the design and manufacturing industry as a whole?

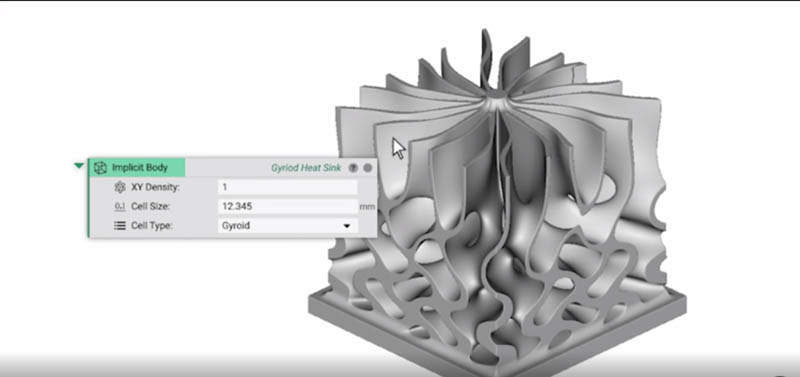

Using nTopology for performance-driven lattice structures

nTopology is a great software to use when it comes to utilizing performance-driven lattice structures in engineering. It’s good to explore their platform to get an insight into how their platform helps engineers put theory into practice that helps design processes and not just the parts themselves.

How are lattice structures used?

As of 2021, 3D printing comprised around 0.1% of the global manufacturing market. A very small amount but in relation to its market size valued, it’s worth well over 14 billion USD.

Lattice structures assist in the processes that engineers go through to help enhance the performance of their products.

There are lots of different lattice types available and any one of them can be incorporated into the engineering process to widen the horizons from a design point of view. With the assistance of latticing techniques, the mass of the product can be reduced by 90% or more by fine-tuning the parameters of the lattice to the physical loads found on each product.

With the right toolset, engineers can develop highly functional and innovative products that help to revolutionize the market as we know it.

The benefits of lattice structures in engineering

Within 3D printing, lattice structures can be extremely helpful for engineering purposes. As such, there are many benefits to using them within the design process of any part or product, especially when the design process can be done through software, rather than wasting materials or resources used to create multiple prototypes.

Here are some of the benefits behind using lattice structures and why it’s likely a method that’s growing so much in popularity within 3D printing.

Reduces wastage

With 3D printing, a lot of resources such as the materials used can be minimal. This is due to the fact that most of it is being designed via software before even being printed. If this were all done manually, there would likely be more materials used and more waste in general.

With lattice structures, it can help engineers choose the right materials. Each material has its own properties, from its weight to how rigid it is. It can help to pick the materials that are best suited for its purpose. Lattice structures help allow for a greater range when it comes to design.

For some engineers, the materials available may be limited or budget and spending may be restricted. It’s a good way of making the most of what’s possible.

There are structural advantages

Lattice structures help to substratialy reduce the mass weight of the part. It’s lightweight arrangements can help achieve the perfect balance along with a variety of different design possibilities.

They help to provide a good amount of space with low materiall usage. It can improve the design opportunities without having tvo use so much of the materials.

There’s a lot of control that can be had when it comes to controlling impact, dampening down noises or vibrations and shock absorption. Engineers can also make use of additional design features that don’t need to compromise the key elements of the part itself.

With so many benefits to using lattice structures in 3D printing, it certainly makes sense as to why it’s being used so much in today’s manufacturing industry. Saving on materials that cost a business money is surely music to any company’s ears!

Examples of how lattice structures are used in additive manufacturing

There are plenty of ways in which lattice structures are being used in additive manufacturing. Here are just a couple of key industries in which they’re being utilized by engineers in the modern day.

Vehicle manufacturing

A lot of vehicle manufacturing parts rely on 3D printing in particular. They use lattice structures in order to lighten the metallic structures that are so often used with vehicle construction.

For aerospace, aviation and automotive, all industries are becoming increasingly competitive in providing the latest possible structures in order to help improve speed and to ensure fuel efficiency remains at the top of the list.

Porsche as an example is one car manufacturer that has created 3D printed parts. Their 3D printed custom seats for example were prototyped for use on race tracks in Europe back in 2020 and street-legal models for 2021.

Architecture

Many companies in the archtecitural world have been taking advantage of lattice structure in relation to the design and build of architectural parts.

A good example of this is in the Milan Design Week back in 2019. A fashion brand called COS commissioned Conifera, a lattice-based structure made out of sustainable bioplastic. As a result, it was the largest 3D printed structures in the world. It helped showcase how lattice structures captured a large surface areas with little materials used.

Another great example of how this form of 3D printing is being utilized for good is the Kakuma Refugee Camp in Keyna. 3D printings of buildligns that made use of little material but providing ample space for these refugees to live in.

Sportswear

Sportsweaar is another fashion sector to embrace 3D printing using lattice structures. For example, Adidas’ Futurecraft 4D shoes are a prime example of how this additive manufacturing is being used for footwear midsoles.

Due to the soft bouncy quality of lattice design along with it’s high strength integrity, they’re the ideal fit for running shoes.

There’s also a lot happening within sports equipment when it comes to 3D printing too. We could see a lot of the equipment we use in the fuutre, having a connsiderable amount of additive manufacturing influence.

How will additive manufacturing change in the future?

Many experts have chimed in on their thoughts when it comes to additive manufacturing in the future.

Naresh Shanker, the Chief Technology Officer at Xerox claims that 3D printing is likely to become fully integrated within traditional manufacturing. With faster and more put together 3D printing, what we’ll see is a consistency in high-quality output of products in the future.

With the rising costs of shipping and the limitations that many businesses face when it comes to distribution, have prompted the need for change. The impact of 3D printing although small to begin with, is likely going to be a dominant feature in mmannufacturing in the years to come.

With a need for lowering costs, whilst maintaing quality and improving sustainbility, is likely going to require more businesses needing additive manufacturing in 2022 and beyond.

The power of lattice structures in additive manufacturing is significant

There is a power that comes with lattice structures that expands the capabilities of more companies that are responsible for engineering. It utilizes minimal materials and can help reduce spend within any project or part development within manufacturing.

Keeping costs and resources down is a great way to help smaller businesses and to help provide parts that wil help those initiatives that need support. Alternatively, they can help power the future of engineering in a more sustainable and environmentally-friendly way.

Lattice stuctures will no doubtedly be used more and more with the advanceemnts in software and technology that provide this as part of their toolkit. It’s worth exploring the variety of software available that provides lattice structures for engineers and designers.