In the manufacturing business world, nowadays, three vital things matter the most to be successful in what you do, price, quality, and effectiveness.

The first one refers to the price of your products which is essential because you will need to offer your products at a price that represents a perfect balance between affordability and profitability.

Second, quality refers to the mechanical and functional properties of the goods you’re producing and trying to put on shelves. And to attract customers who’ll prefer your products rather than buying from your competitors, your items must be of premium quality.

Lastly, the effectiveness of your entire manufacturing process as a whole is also unbelievably significant. Nevertheless, achieving effective manufacturing is a challenging task because it requires vast amounts of time and money.

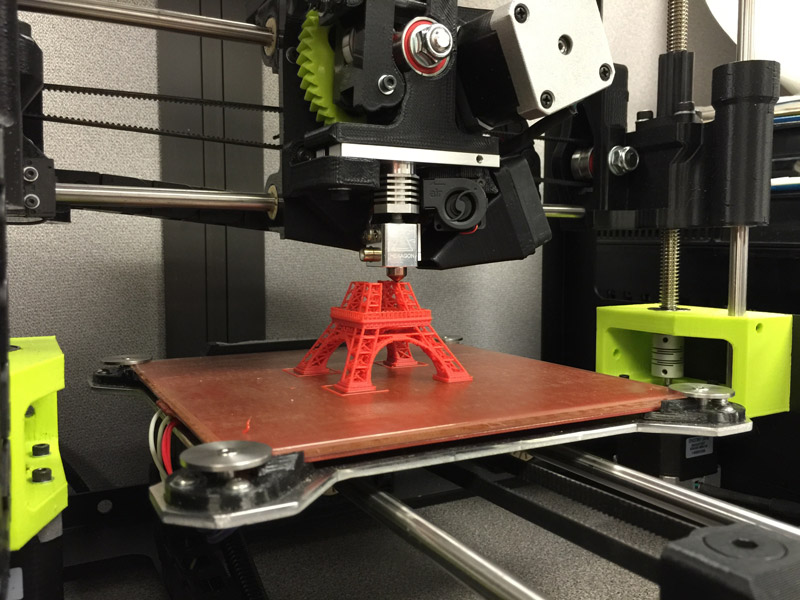

Photo from Medium

To achieve all three, you need to find the proper manufacturing technique to produce and deliver your finished products to your clients on time. In this process, time is of the essence because if you fail to provide your products as agreed upon, your fierce rivals will waste no time whatsoever and capture your market share in weeks, if not days.

Enter rapid prototyping and rapid manufacturing. Only rapid prototyping services for rapid manufacturing purposes can provide your manufacturing business with all three fundamentals. Rapid prototyping is a modern-day product development technique that permits engineers and designers to compress design timelines and reach faster final production-ready designs.

Below, we’ll explain the top advantages of this groundbreaking manufacturing technique and how it can benefit your future product development projects.

Rapid Prototyping Is a Time-Saving Technique

As they say, time is money, and rapid prototyping is a real-time-saving technique that can permit your business to market brand new products in shorter periods. As soon as you get rid of the time required to produce in-house molds, tools, and patterns for conventional in-house prototyping and decide to transfer the time-consuming work to specialized companies that offer prototype services, your operation will experience a massive time reduction between the preliminary design stage until the product goes into mass production.

Photo from The Product Manager

If there’s any need, the rapid prototyping technique will let your engineers and designers quickly modify and change the prototype according to the feedback they’ll get from the produced prototype. As time-saving is essential for modern-age businesses, companies that will develop new product designs faster than their competitors will always have a competitive advantage, and rapid prototyping makes that possible.

You Will Better Understand the Final Product

As soon as you get the idea of what your final product should look like and its core functions, rapid prototyping can lead to improved functionality of the model and better overall performance of the concluded product.

In addition, by permitting designers and engineers to understand their ideas beyond virtual visualization, rapid prototypes can help them better know the design’s final look and feel what their product looks like instead of just assuming if they use a computer-aided illustration to visualize their concept.

Your BusinessCan Save a Lot of Money

Rapid prototyping can help your company decrease product development and manufacturing expenses, as you will no longer necessitate developing novel tools for each new product you want to prototype. That’s because the rapid prototyping technique utilizes the same CAD and 3D machinery each time when you want to develop a new product prototype in a flash.

In addition, rapid prototyping can help you reduce the costs for your operational staff and the rarely calculated costs of waste. While conventional prototyping techniques create tons of waste through chippings and cut-off materials, rapid prototyping creates only the final model, providing you with an opportunity to cut costs even more.

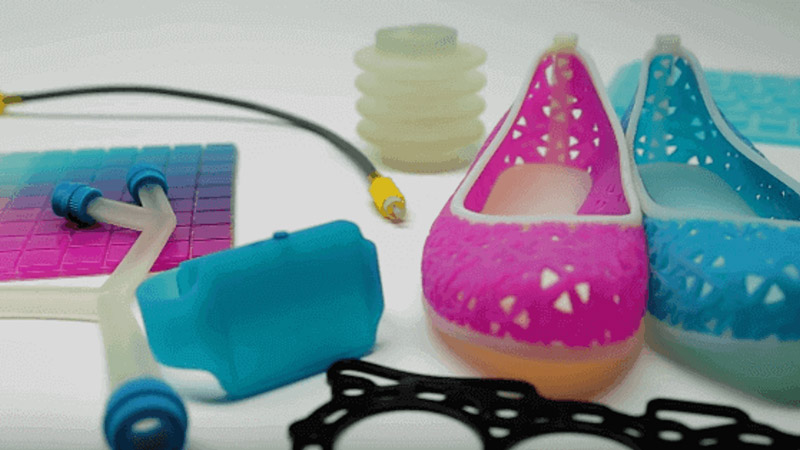

With Rapid Prototyping You Can Test Various Materials for Your Final Product

Last but not least, rapid prototyping technology can enable you to choose from a wide variety of materials for your prototype and create it in the same manner as you will in the final production environment. These materials vary from nylon to aluminum, steel, and more. Aluminum and steel are metal composites that can withstand the stresses and temperatures typical for aerospace and automotive components.

Moreover, the rapid prototyping process can offer up to 200 different combinations of materials, shades, and finishes, from which engineers and skilled product designers can create their new product designs for nearly all industrial sectors.

Photo from ResearchGate

Conclusion

Rapid prototyping models can save you a lot of money and time, help you better understand the product, and permit you to test various materials for your final design. As a result, numerous industries like automotive, construction, healthcare, and more, regularly utilize the rapid prototyping technique before committing to the mass-production of a new component or product.